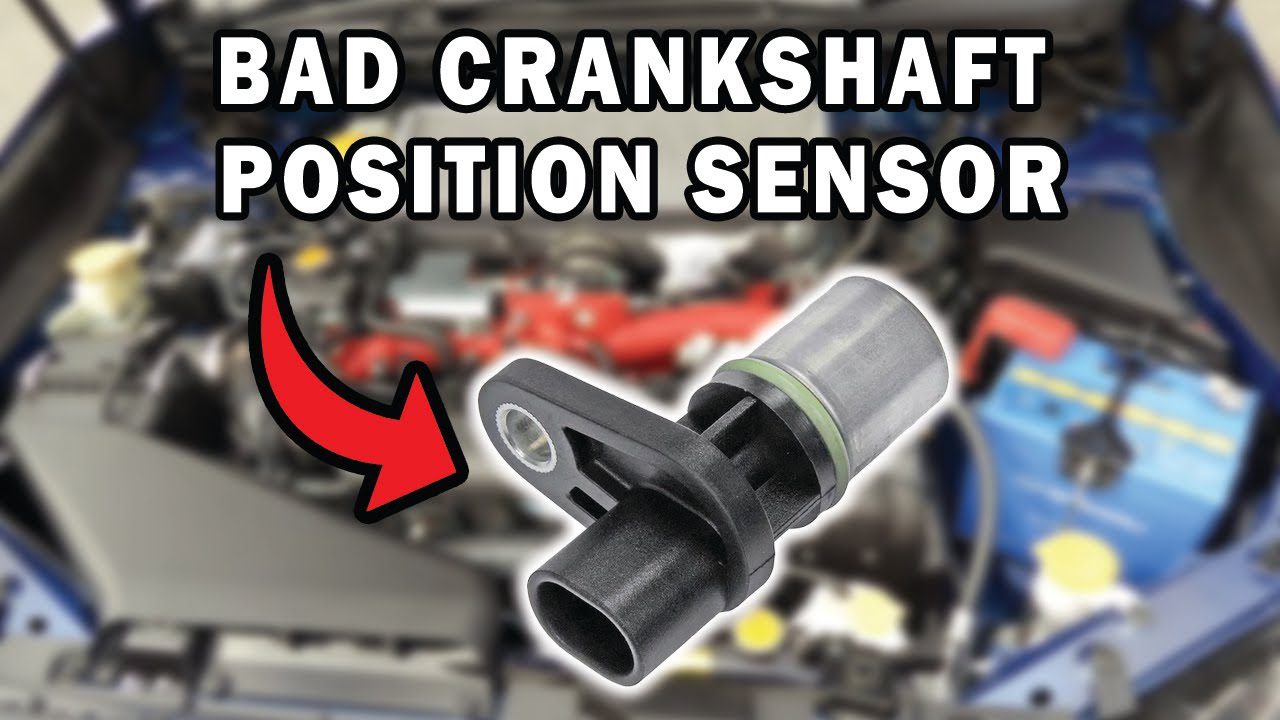

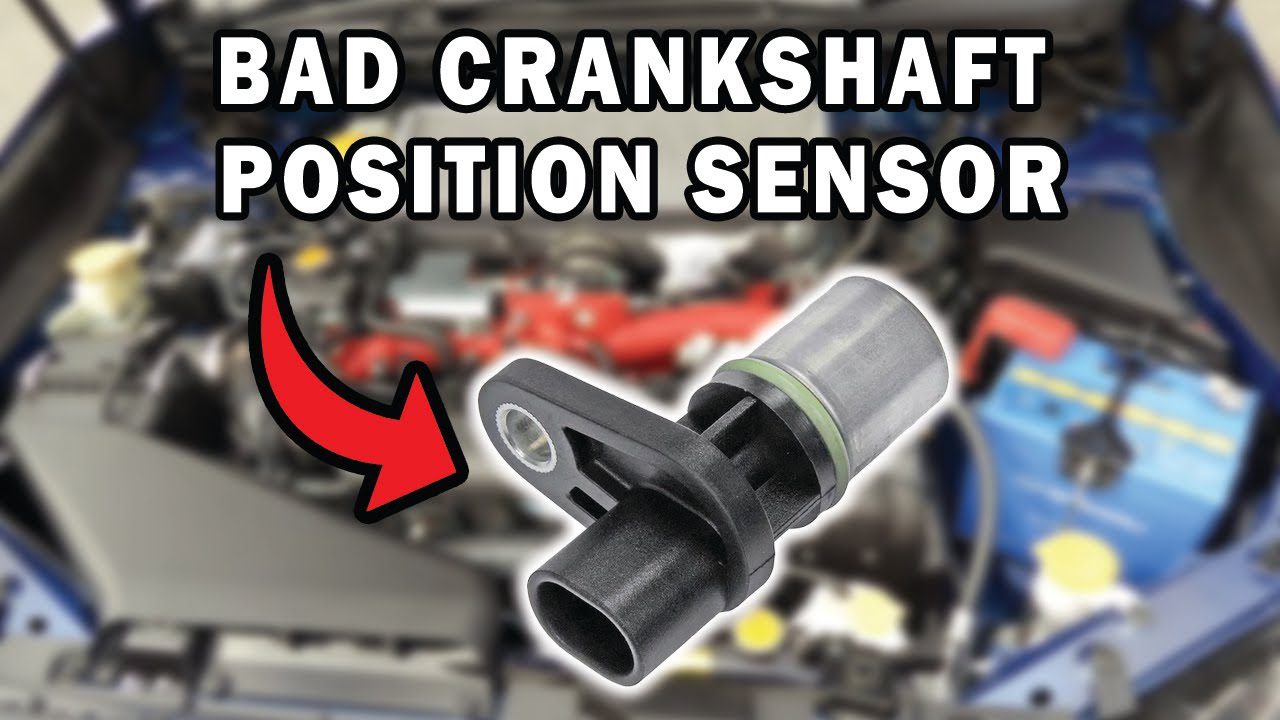

Symptoms of a bad crankshaft position sensor

The most common symptoms of a bad crankshaft position sensor include issues starting the vehicle, intermittent stalling, and the Check Engine Light coming on.

The crankshaft position sensor is an element of engine control that is present in almost all current internal combustion engines. It keeps track of the crankshaft’s location and rate of rotation and transmits that data to the engine management unit so that it can modify as necessary depending on the operating circumstances.

Many engines cannot run if the crankshaft position sensor does not output an accurate signal since the crankshaft speed and position are some of the most crucial factors used in engine management calculations.

READ MORE: Steering Wheel Hard To Turn: Causes, Solution

Crankshaft position sensor faults might be related to a number of different problems. 2 typical causes are as follows:

Engine overheating: By melting the plastic covering on the crankshaft sensor, an overheated engine may cause damage.

Circuitry issues: The crankshaft sensor may experience problems if there is faulty voltage or if the wire is loose, worn out, or broken.

It can be challenging and potentially dangerous to drive with a crankshaft position sensor that is malfunctioning. It can result in expensive, long-lasting repairs or possibly cause the car to stop functioning altogether.

Usually, a crankshaft position sensor issue will result in one or more of the seven symptoms listed below, which should serve as a warning to the driver.

1. Issues Starting the Vehicle

Starting problems are the most frequent sign of a defective or failed crankshaft position sensor. The crankshaft position sensor keeps track of the crankshaft’s position, speed, and other elements that are crucial for starting the engine.

The car can start intermittently or not at all if the crankshaft position sensor isn’t working properly.

2. Intermittent Stalling

Intermittent stalling is a different symptom frequently connected to a crankshaft position sensor issue. The crankshaft signal may be interrupted while the engine is operating due to problems with the crankshaft position sensor or its wiring, which could lead to an engine stall.

This typically indicates a wiring issue. However, this symptom might also be caused by a malfunctioning crankshaft position sensor.

3. Check Engine Light Comes On

An illuminated Check Engine Light is another sign that there might be a problem with the crankshaft position sensor. The computer will turn on the Check Engine Light to warn the driver if it notices an issue with the crankshaft position sensor’s signal.

Numerous other problems might also cause the Check Engine Light to come on. It is very advised to get the computer scanned for issue codes.

4. Uneven Acceleration

The engine control unit cannot adjust the spark timing and fuel injection when the engine speed increases if the crankshaft position sensor’s input is wrong.

Lack of accuracy can lead to slow or uneven acceleration, which makes it challenging to maintain a constant pace.

5. Engine Misfires or Vibrates

A stuttering sound or sensation in the engine could indicate that the crankshaft position sensor is malfunctioning, which could result in misfired cylinders.

A cylinder will misfire if the crankshaft position sensor isn’t functioning properly because it can’t tell where the pistons are in the engine. Although incorrect spark plug timing is another possibility, the crankshaft sensor is more likely to be the culprit if the spark plugs are examined.

6. Rough Idle and/or Vibrating Engine

Rough idling is another indication of a crankshaft position sensor issue. You might hear the engine groaning or vibrating while stopped or idling at a red light.

This indicates that the sensor is not keeping track of the crankshaft’s position, which results in vibrations that reduce total engine output. Additionally, the shaking may obstruct the engine’s ability to track mileage.

Any unusual vibrations should be checked out as soon as possible by a professional.

7. Reduced Gas Mileage

Fuel injectors won’t efficiently pump gas into the engine if the crankshaft position sensor doesn’t provide appropriate timing data.

On both short and long trips, the engine will use more fuel than is necessary, lowering overall fuel efficiency. Have a mechanic check the sensor because poor fuel economy can also result from other problems.

Due to the crucial signal, it gives for engine calculations, the crankshaft position sensor is essential for proper engine functionality and performance.

Crankshaft sensor problems can swiftly develop into issues that impair the vehicle’s ability to drive. Because of this, you should have your car checked out by a qualified mechanic as soon as you suspect there may be a problem with the crankshaft position sensor.

They will be able to diagnose your car and replace your crankshaft position sensor if necessary.

Symptoms of a bad crankshaft position sensor